ZERO POINT SHAFT

Axle shaft pursuing the highest performance

Compatible models are over 3000 models.There are "Zero Point Shaft"and"Zero Point Shaftμ".The lineup is increasing at any time.Please check the website for the latest information on compatible models.As for the bolt head shape for the front, there is a model that can select the hex lobe type in addition to the genuine type.

Standard model of ZERO POINT SHAFT

As material, alloy steel SCM 435 for machine structural use (according to ISO 683-1, ISO 683-11) is used. They are steel materials most suitable for axle shafts. It is manufactured with high precision processing at the nano level, ensuring high lubricity and optimum clearance dimension. Their coefficient of friction is about half of the general axle shaft, boasting amazing low friction.

Surface treatment of ZERO POINT SHAFT

Is special plating of three layers. The first layer "electroless nickel plating" is superior in dimension accuracy control, so accurate dimension management as designed is possible. In addition, because the surface treatment is uniformly applied to the entire object, plating inside the cylinder is possible. The second layer "black chrome plating" makes nano-level irregularities on the surface, Improving oll retention. Matte black is charm. The third layer uses a special plating process only with "ZERO POINT SHAFT".

ZERO POINT SHAFT μ

is the finest quality product that used special carefully selected shafts as raw materials and subjected to special surface treatment.They are loaded with technologies that are also used in races in the world such as MotoGP, SBK and Isle of Man TT. Because mass production is impossible for these, it takes time for delivery.

Products by brand

HONDA

YAMAHA

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| FJR1300/A /AS | '06- | Front | A | |

| FJR1300/A /AS | '06- | Front | A1 | H-100 |

| FJR1300 | '06- | Rear | A | |

| FJR1300 | '06- | Rear | A1 | H-100 |

| FZ1/N /S | '06- | Front | A | |

| FZ1/N /S | '06- | Front | A1 | H-100 |

| FZ1 | '06- | Pviot | S | |

| FZ1 | '06- | Rear | E | |

| FZ6/N /S Fazer /SS Fazer | Front | A | ||

| FZ6/N /S Fazer /SS Fazer | Front | A1 | H-100 | |

| FZ6 | Pviot | S | ||

| FZ6/N /S Fazer /SS Fazer | '07-'09 | Rear | E | |

| FZ8/N /NA /S /SA | '11- | Front | A | |

| FZ8/N /NA /S /SA | '11- | Front | A1 | H-90 |

| FZ8 | Pviot | S | ||

| FZ8 | '11- | Rear | E | |

| FZS600/S /SP | '00-'03 | Front | A | |

| FZS600 | '00-'03 | Rear | E | |

| FZS1000FAZER | Front | A | ||

| FZS1000FAZER | Front | A1 | H-100 | |

| FZS1000FAZER | Rear | E | ||

| FZR750 | '87-'88 | Front | A | |

| FZR1000 | '87-'88 | Front | A | |

| FZR1000 | '89-'90 | Front | A | |

| FZR1000 | '89-'93 | Rear | E | |

| MT-01/S | '05-'09 | Front | A | |

| MT-01/S | '05-'09 | Front | A1 | H-100 |

| MT-01/S | '05-'09 | Pviot | S | |

| MT-01/S | Rear | E | ||

| MT-125 | '15- | Front | E | * Confirm the genuine part number * Confirm the shape |

| MT-125 | '15- | Front | E | * Confirm the genuine part number * Confirm the shape |

| MT-125 | '15- | Rear | E | |

| MT-15(M-SLAZ 150) | '16-'19 | Front | E | |

| MT-15(M-SLAZ 150) | '16-'18 | Pviot | E | |

| MT-15(M-SLAZ 150) | '16-'18 | Rear | E | |

| MT-15(M-SLAZ 150) | 2019 | Pviot | E | |

| MT-15(M-SLAZ 150) | 2019 | Rear | E | |

| MT-25 | Front | E | ||

| MT-25 | Rear | E | ||

| MT-25 | Pviot | S | ||

| MT-03 | Front | E | ||

| MT-03 | Rear | E | ||

| MT-03 | Pviot | S | ||

| MT-07/A | '14- | Front | E | |

| MT-07/A | '14- | Pviot | S | |

| MT-07/A | '14- | Rear | E | |

| MT-09/TRACER | '14- | Front | A | |

| MT-09/TRACER | '14- | Front | A1 | H-90 |

| MT-09/TRACER | '14-'16 | Rear | E | |

| MT-09 | '17- | Rear | E | |

| MT-09/TRACER | '14- | Pviot | S | |

| MT-10/SP | '17- | Front | B | |

| MT-10/SP | '17- | Pviot | S | |

| MT-10/SP | '17- | Rear | E | |

| NIKEN(MXT850) | '18- | Front | S | 1SET |

| NIKEN(MXT850) | '18- | Pviot | S | |

| NIKEN(MXT850) | '18- | Rear | E | |

| NMAX155 | Front | E | ||

| R1-Z | Front | D | ||

| R1-Z | Rear | E | ||

| RZ250 | Front | D | Specifications :hexagon castle nut | |

| RZ250 | Pviot | S | No Grease nipple | |

| RZ250 | Rear | D | Specifications :hexagon castle nut | |

| RZV500R_V4 | Front | E | ||

| RZV500R_V4 | Rear | E | ||

| SR400 | '01- | Front | A | |

| SR400 | '01- | Front | A1 | H-90 |

| SR400 | '01- | Pviot | S | |

| SR400 | '01- | Rear | E | |

| TRACER900/GT | '18- | Front | A | |

| TRACER900/GT | '18- | Front | A1 | H-90 |

| TRACER900/GT | '18- | Pviot | S | |

| TRACER900/GT | '18- | Rear | E | |

| TDM900/A | '07-'10 | Front | A | |

| TDM900/A | '07-'10 | Front | A1 | H-100 |

| TDM900/A | '07-'10 | Rear | E | |

| Tricity125,155 | Front | B | 1SET | |

| TRX850 | Front | E | ||

| TRX850 | Rear | E | ||

| TZR250 | '85-'87 | Front | D | Not 10W-25181-00 |

| TZR250 | '85-'88 | Rear | E | |

| TZR250 | 1989 | Front | E | |

| TZR250 | '89-'90 | Rear | E | |

| TZR250/R /RS | '91-'95 | Front | A | |

| TZR250/R /RS | '91-'95 | Front | A1 | H-80 |

| TZR250 | 1995 | Rear | E | TZRSPR Specifications :Self-locking nut |

| WR250/R /X | '07- | Front | A | |

| WR250/R /X | '07- | Front | A1 | H-80 |

| WR250/R /X | '07- | Rear | E | |

| WR250F | '06-'09 | Front | A | |

| WR250F | '06-'09 | Front | A1 | H-90 |

| WR250F | '07-'09 | Rear | E | |

| WR450F | '06-'09 | Front | A | |

| WR450F | '06-'09 | Front | A1 | H-90 |

| WR450F | '07-'09 | Rear | E | |

| WR450F | '13- | Front | A | |

| WR450F | '13- | Front | A1 | H-90 |

| WR450F | '13- | Rear | E | |

| XC125(Cyguus)/SR | '03- | Front | E | |

| XC155(Majesty155)/SR | '14- | Front | E | |

| XMAX | '18- | Front | E | |

| XP500(T-MAX500) | '01-'07 | Front | A | |

| XP500(T-MAX500) | '01-'07 | Front | A1 | H-80 |

| XP500(TMAX500) | '01-'12 | Rear | A | |

| XP500(TMAX500) | '01-'12 | Rear | A1 | H-80 |

| XP500(TMAX500) | '08-'12 | Front | A | |

| XP500(TMAX500) | '08-'12 | Front | A1 | H-100 |

| XP530(TMAX530) | '11-'14 | Front | A | |

| XP530(TMAX530) | '11-'14 | Front | A1 | H-100 |

| XP500 WGP50 | 2012 | Front | A | |

| XP500 WGP50 | 2012 | Front | A1 | H-100 |

| XP530(TMAX530) | '12-'16 | Rear | E | |

| XP530(TMAX530) | '15-'19 | Front | A | |

| XP530(TMAX530) | '15-'19 | Front | A1 | H-100 |

| XP530(TMAX530) | '17-'19 | Front | A | |

| XP530(TMAX530) | '17-'19 | Front | A1 | H-100 |

| XP530(TMAX530) | '17-'19 | Rear | E | |

| XP560(TMAX560) | '20- | Front | A | |

| XP560(TMAX560) | '20- | Front | A1 | H-100 |

| XP560(TMAX560) | '20- | Rear | E | |

| XP500A | Front | A | ||

| XP500A | Front | A1 | H-100 | |

| XJ6 F/FA/N/NA/S/SA | '09- | Front | A | |

| XJ6 | '09- | Rear | E | |

| XJR1200 | Front | E | ||

| XJR1200 | Pviot | S | ||

| XJR1200 | Rear | E | ||

| XJR1300 | '98-'99 | Front | E | |

| XJR1300 | '98-'15 | Pviot | S | |

| XJR1300 | '98-'99 | Rear | E | |

| XJR1300/SP | '00-'15 | Front | A | |

| XJR1300/SP | '00-'15 | Front | A1 | H-100 |

| XJR1300 | '00-'06 | Rear | E | |

| XJR1300 | '07-'15 | Rear | E | |

| XG250(TRICKER) | '04- | Front | E | |

| XG250(TRICKER) | '04- | Pviot | S | |

| XG250(TRICKER) | '04- | Rear | E | |

| XSR155 | '19- | Front | E | |

| XSR155 | '19- | Pviot | E | |

| XSR155 | '19- | Rear | E | |

| XSR700 | '17- | Front | E | |

| XSR700 | '17- | Pviot | S | |

| XSR700 | '17- | Rear | E | |

| XSR900 | '16- | Front | A | |

| XSR900 | '16- | Front | A1 | H-90 | XSR900 | '16- | Pviot | S |

| XSR900 | '16- | Rear | E | |

| XT225WE(SEROW225) | '97-'04 | Front | E | Specifications :Self-locking nut |

| XT225WE(SEROW225) | '97-'04 | Rear | E | Specifications :Self-locking nut |

| XT250(SEROW250) | '05-'07 | Front | E | /SERROW250,SERROW250S,X |

| XT250(SEROW250) | '05- | Pviot | S | |

| XT250(SEROW250) | '08- | Front | E | |

| XT250(SEROW250) | '05- | Rear | E | |

| XT1200Z (SuperTe'ne're' ) | Front | A | ||

| XT1200Z (SuperTe'ne're' ) | Front | A1 | H-100 | |

| XT1200Z (SuperTe'ne're' ) | Rear | E | ||

| XVS125(DragStar) | Front | E | ||

| XVS250(DragStar) | Front | E | ||

| XVS950CU (BOLT) | '14- | Front | E | |

| XVS950CU (BOLT) | '14- | Rear | E | |

| XVS950XR (SCR950) | '17- | Front | E | |

| XVS950XR (SCR950) | '17- | Rear | E | |

| XV1900(DragStar)/A /CU | '06- | Front | A | |

| XV1900(DragStar)/A /CU | '06- | Front | A1 | H-100 |

| XV1900(DragStar) | '06- | Rear | E | |

| XVS1300CU(DragStar) | 2013 | Front | A | |

| XVS1300CU(DragStar) | 2013 | Front | A1 | H-100 |

| XVS13CA(DragStar) | 2011 | Front | A | |

| XVS13CA(DragStar) | 2011 | Front | A1 | H-100 |

| XVS13CB(DragStar) | 2012 | Front | A | |

| XVS13CB(DragStar) | 2012 | Front | A1 | H-100 |

| VMX12 (VMAX1200) | '85- | Front | E | |

| VMX12 (VMAX1200) | '85-'97 | Rear | B | H-100 Specifications :Self-locking nut |

| VMX12 (VMAX1200) | '98-'07 | Rear | A | |

| VMX12 (VMAX1200) | '98-'07 | Rear | A1 | H-100 |

| VMX17 (VMAX1700) | '09- | Front | A | |

| VMX17 (VMAX1700) | '09- | Front | A1 | H-100 |

| VMX17 (VMAX1700) | '09- | Rear | A | |

| VMX17 (VMAX1700) | Rear | A1 | H-100 | |

| YZ65 | '18- | Pviot | E | |

| YZ65 | '18- | Rear | E | |

| YZ85 /LW | '02-'19 | Front | E | |

| YZ85 /LW | '02-'18 | Pviot | E | |

| YZ85 /LW | '02-'18 | Rear | E | |

| YZ85 /LW | 2019 | Pviot | E | |

| YZ85 /LW | 2019 | Rear | E | |

| YZ125 | '05-'07 | Front | B | |

| YZ125 | '05- | Pviot | S | |

| YZ125 | '05- | Rear | B | |

| YZ125 | '08- | Front | B | |

| YZ125X | '17- | Front | B | |

| YZ125X | '17- | Pviot | S | |

| YZ125X | '17- | Rear | B | |

| YZ250FX | '15- | Front | B | |

| YZ250FX | '15- | Pviot | S | |

| YZ250FX | '15- | Rear | B | |

| YZ250X | '16- | Front | B | |

| YZ250X | '16- | Pviot | S | |

| YZ250X | '16- | Rear | B | |

| YZ450F | '05-'07 | Front | B | |

| YZ450F | '06-'09 | Pviot | S | |

| YZ450F | '05-'08 | Rear | B | |

| YZ450F | '08-'13 | Front | B | |

| YZ450F | '09- | Rear | B | |

| YZ450F | '10- | Pviot | S | |

| YZ450F | '14- | Front | B | |

| YZ450FX | '16- | Front | B | |

| YZ450FX | '16- | Pviot | S | |

| YZ450FX | '16- | Rear | B | |

| YZF-R1 | '98-'01 | Front | A | |

| YZF-R1 | '98-'01 | Front | A1 | H-100 |

| YZF-R1 | '98-'03 | Pviot | S | |

| YZF-R1 | '98-'03 | Rear | E | |

| YZF-R1 | '02-'06 | Front | A | |

| YZF-R1 | '02-'06 | Front | A1 | H-100 |

| YZF-R1 | '04-'06 | Rear | E | |

| YZF-R1 | '07-'14 | Front | A | |

| YZF-R1 | '07-'14 | Front | A1 | H-100 |

| YZF-R1 | '07-'14 | Rear | E | |

| YZF-R1 | '07-'08 | Pviot | S | |

| YZF-R1 | '07-'08 | Pviot | S1 | H-100 |

| YZF-R1 | '09- | Pviot | S | |

| YZF-R1 | '09- | Pviot | S1 | H-100 |

| YZF-R1 | '15- | Front | B | |

| YZF-R1 | '15- | Rear | E | |

| YZF-R125 | '08- | Front | E | * Confirm the genuine part number * Confirm the shape |

| YZF-R125 | '08- | Front | E | * Confirm the genuine part number * Confirm the shape |

| YZF-R125 | '08- | Rear | E | |

| YZF-R15 | '08- | Front | E | |

| YZF-R15 | '08-'14 | Rear | E | |

| YZF-R15(YZF155) | '17- | Front | E | |

| YZF-R15(YZF155) | '17- | Pviot | E | |

| YZF-R15(YZF155) | '17- | Rear | E | |

| YZF-R25 | Front | E | ||

| YZF-R25 | Rear | E | ||

| YZF-R25 | Pviot | S | ||

| YZF-R3 | Front | E | ||

| YZF-R3 | Rear | E | ||

| YZF-R3 | Pviot | S | ||

| YZF-R6 | '99-'02 | Front | A | |

| YZF-R6 | '99-'02 | Front | A1 | H-100 |

| YZF-R6 | '99-'05 | Pviot | S | |

| YZF-R6 | '99-'02 | Rear | E | |

| YZF-R6 | '03-'04 | Front | A | |

| YZF-R6 | '03-'04 | Front | A1 | H-100 |

| YZF-R6 | '03-'05 | Rear | E | |

| YZF-R6 | '05-'16 | Front | A | |

| YZF-R6 | '05-'16 | Front | A1 | H-100 |

| YZF-R6 | '06- | Pviot | S | |

| YZF-R6 | '06-'16 | Rear | E | * Confirm the genuine part number |

| YZF-R6 | '17- | Front | B | |

| YZF-R6 | '17- | Rear | E | |

| YZF-R6S | '07-'09 | Front | A | |

| YZF-R6S | '07-'09 | Front | A1 | H-100 |

| YZF-R6S | '07-'09 | Rear | E |

SUZUKI

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| DL650 (V-STROM650) | '03-'16 | Front | B | Not 54711-08F10 |

| DL650 (V-STROM650) | '03-'16 | Front | B | Not 54711-08F00 |

| DL650 (V-STROM650) | '17- | Front | B | |

| DL650 (V-STROM650) | Rear | E | ||

| DR-Z400/S /E /SM /SY | Front | A | ||

| DR-Z400/S /E /SM /SY | Front | A1 | H-90 | |

| DR-Z400SM | Rear | E | ||

| Gixxer 150 | Front | E | ||

| Gixxer 150 | Rear | E | ||

| GLADIUS400 | Front | B | Not 54711-08F10 | |

| GLADIUS400 | Rear | E | ||

| GLADIUS650 | Front | B | Not 54711-08F10 | |

| GLADIUS650 | Rear | E | ||

| GS1200SS | Front | A | ||

| GS1200SS | Front | A1 | H-100 | |

| GS1200SS | Pviot | S | ||

| GS1200SS | Rear | E | ||

| GSF400(GK75,GK7AA) | '89-'97 | Front | B | |

| GSF600 | '95-'99 | Front | B | |

| GSF1200(GV75) | '95-'99 | Front | A | Not TypeABS |

| GSF1200(GV75) | '95-'99 | Front | A1 | H-100 Not TypeABS |

| GSF1200(GV75) | '95-'99 | Rear | E | |

| GSF1200(GV77) | '00-'05 | Front | A | Not TypeABS |

| GSF1200(GV77) | '00-'05 | Front | A1 | H-100 Not TypeABS |

| GSF1200(GV77) | '00-'05 | Rear | B | |

| GSF1200(GV79) | 2006 | Front | A | |

| GSF1200(GV79) | 2006 | Front | A1 | H-100 |

| GSF1200(GV79) | 2006 | Rear | E | |

| GSF1250S | '07-'16 | Front | A | |

| GSF1250S | '07-'16 | Front | A1 | H-100 |

| GSF1250S | '07-'16 | Rear | E | |

| GSR600 | Front | A | ||

| GSR600 | Front | A1 | H-100 | |

| GSR600 | Pviot | S | ||

| GSR600 | Pviot | S1 | H-100 | |

| GSR750 | Front | A | ||

| GSR750 | Front | A1 | H-100 | |

| GSR750 | Rear | E | ||

| GSX-250R | Front | A | ||

| GSX-250R | Front | A1 | H-90 | |

| GSX-250R | Rear | E | ||

| GSX400(IMPLUSE) | '94-'99 | Front | B | |

| GSX400S KATANA | '92-'99 | Front | B | |

| GSX600F KATANA | '03-'06 | Front | B | Not 54711-08F10 |

| GSX750F KATANA | '03-'06 | Front | B | Not 54711-08F10 |

| GSX750S(KATANA750 S1) | 1982 | Front | B | |

| GSX750S(KATANA750 S1) | 1982 | Rear | B | |

| GSX1100G | '91-'94 | Front | B | |

| GSX1100S(KATANA1100S) | Front | B | ||

| GSX1100S(KATANA1100S) | Rear | B | ||

| GSX-1250 | '07- | Front | A | |

| GSX-1250 | '07- | Front | A1 | H-100 |

| GSX-1250 | '07- | Rear | E | |

| GSX1300R | '99-'03 | Front | A | |

| GSX1300R | '99-'03 | Front | A1 | H-100 |

| GSX1300R | '99-'02 | Pviot | S | |

| GSX1300R | '99-'07 | Rear | D | |

| GSX1300R | '03- | Pviot | S | |

| GSX1300R | '04-'07 | Front | A | |

| GSX1300R | '04-'07 | Front | A1 | H-100 |

| GSX1300R | '08- | Front | A | |

| GSX1300R | '08- | Front | A1 | H-100 |

| GSX1300R | '08- | Rear | E | |

| GSX1400 | Front | A | ||

| GSX1400 | Front | A1 | H-100 | |

| GSX1400 | Rear | E | ||

| GSX-R125 | Front | E | ||

| GSX-R125 | Rear | E | ||

| GSX-R150 | Front | E | The base motorcycle is GSX-R125. | |

| GSX-R150 | Rear | E | The base motorcycle is GSX-R125. | |

| GSX-R150 | Front | E | The base motorcycle is Gixxer150. | |

| GSX-R150 | Rear | E | The base motorcycle is Gixxer150. | |

| GSX-R400 | '90- | Front | A | |

| GSX-R400 | '90- | Front | A1 | H-80 |

| GSX-R600 | '97-'00 | Front | A | |

| GSX-R600 | '97-'00 | Front | A1 | H-100 |

| GSX-R600 | '97-'04 | Pviot | S | |

| GSX-R600 | '97-'00 | Rear | E | Specifications :Self-locking nut |

| GSX-R600 | '01-'05 | Front | B | |

| GSX-R600 | '01-'05 | Rear | D | Specifications :hexagon castle nut |

| GSX-R600 | 2005 | Pviot | S | |

| GSX-R600 | '06-'09 | Front | A | |

| GSX-R600 | '06-'09 | Front | A1 | H-100 |

| GSX-R600 | '06- | Pviot | S | |

| GSX-R600 | '06- | Pviot | S1 | H-100 |

| GSX-R600 | '06-'09 | Rear | E | |

| GSX-R600 | '12- | Front | A | |

| GSX-R600 | '12- | Front | A1 | H-100 |

| GSX-R600 | '12- | Front | B | Ver.Light wight |

| GSX-R600 | '11- | Rear | E | |

| GSX-R750 | 1987 | Front | B | |

| GSX-R750 | '85-'87 | Rear | B | |

| GSX-R750 | '88-'90 | Front | A | |

| GSX-R750 | '88-'90 | Front | A1 | H-100 |

| GSX-R750 | '90-'91 | Rear | D | Specifications :hexagon castle nut |

| GSX-R750 | '96-'99 | Front | A | |

| GSX-R750 | '96-'99 | Front | A1 | H-100 |

| GSX-R750 | 1996 | Rear | D | Specifications :hexagon castle nut |

| GSX-R750 | '96-'03 | Pviot | S | |

| GSX-R750 | '97-'99 | Rear | E | Specifications :Self-locking nut |

| GSX-R750 | '00-'05 | Front | B | |

| GSX-R750 | '00-'05 | Rear | D | Specifications :hexagon castle nut |

| GSX-R750 | 2005 | Pviot | S | |

| GSX-R750 | '06-'10 | Front | A | |

| GSX-R750 | '06-'10 | Front | A1 | H-100 |

| GSX-R750 | '06- | Pviot | S | |

| GSX-R750 | '06- | Pviot | S1 | H-100 |

| GSX-R750 | '06-'10 | Rear | E | |

| GSX-R750 | '11- | Front | A | |

| GSX-R750 | '11- | Front | A1 | H-100 |

| GSX-R750 | '12- | Front | B | Ver.Light wight |

| GSX-R750 | '11- | Rear | E | |

| GSX-R1000 | '01-'06 | Front | B | |

| GSX-R1000 | '01-'02 | Pviot | S | |

| GSX-R1000 | '01-'06 | Rear | E | Specifications :Self-locking nut |

| GSX-R1000 | '05-'11 | Front | A | |

| GSX-R1000 | '05-'11 | Front | A1 | H-100 |

| GSX-R1000 | '05-'16 | Pviot | S | |

| GSX-R1000 | '05- | Pviot | S1 | H-100 |

| GSX-R1000 | '07-'08 | Rear | E | |

| GSX-R1000 | '09- | Rear | E | |

| GSX-R1000/R | '12- | Front | A | |

| GSX-R1000/R | '12- | Front | A1 | H-100 |

| GSX-R1000/R | '12- | Front | B | Ver.Light wight |

| GSX-R1000 | '17-'18' | Pviot | S | |

| GSX-R1000 | '17-'18' | Pviot | S1 | H-100 |

| GSX-R1000/R | '19- | Pviot | S | |

| GSX-R1100 | '87-'88 | Front | B | |

| GSX-R1100 | '89-'90 | Front | A | |

| GSX-R1100 | '89-'90 | Front | A1 | H-100 |

| GSX-R1100 | '88-'92 | Rear | D | Specifications :hexagon castle nut |

| GSX-R1100 | '91-'98 | Fornt | A | |

| GSX-R1100 | '91-'98 | Front | A1 | H-100 |

| GSX-R1100 | '93-'94 | Pviot | S | |

| GSX-R1100 | '93-'94 | Rear | E | |

| GSX-S125 | Front | E | ||

| GSX-S125 | Rear | E | ||

| GSX-S1000/F | Front | A | ||

| GSX-S1000/F | Front | A1 | H-100 | |

| GSX-S1000/F | Front | B | Ver.Light wight | |

| GSX-S1000/F | Pviot | S | ||

| GSX-S1000/F | Pviot | S1 | H-100 | |

| GSX-S1000/F | Rear | E | ||

| GSX-S1000S(KATANA) | '19- | Front | B | Ver.Light wight |

| GSX-S1000S(KATANA) | '19- | Pviot | S | |

| GSX-S1000S(KATANA) | '19- | Rear | E | |

| GW250(GSR250) | Front | A1 | H-90 | |

| GW250(GSR250) | Front | A | ||

| GW250(GSR250) | Rear | E | ||

| LS650Savage | Front | A | ||

| LS650Savage | Front | A1 | H-90 | |

| LS650Savage | Rear | B | ||

| RF600 | '93-'97 | Front | B | |

| RGV250(VJ21A) | '93-'97 | Front | B | |

| RGV250(VJ21A) | '93-'97 | Rear | E | |

| RGV250(VJ22A) | '90-'93 | Front | A | L /FL /FNL /M /FM /FNM /N /FN /FNN /P /FP /R |

| RGV250(VJ22A) | '90-'93 | Front | A1 | H-80 L /FL /FNL /M /FM /FNM /N /FN /FNN /P /FP /R |

| RGV250(VJ22A) | '90-'93 | Rear | E | L /FL /FNL /M /FM /FNM /N /FN /FNN /P /FP /R |

| RGV250(VJ23A) | '96- | Front | A | |

| RGV250(VJ23A) | '96- | Front | A1 | H-90 |

| RGV250(VJ23A) | '96- | Pviot | S | |

| RGV250(VJ23A) | '96- | Rear | E | |

| ST400V ( Tempter ) | Front | E | ||

| ST400V ( Tempter ) | Rear | E | ||

| SV1000 | Front | B | ||

| SV1000 | Pviot | S | ||

| SV1000 | Rear | D | Specifications :hexagon castle nut | |

| SV650 | '03- | Front | B | Specifications :H-80 Not 54711-08F10 |

| SV650 | '03- | Front | B | Not 54711-08F00 |

| SV650 | '03- | Rear | E | |

| TL1000 | Front | A | ||

| TL1000 | Front | A1 | H-100 | |

| TL1000 | Rear | E | ||

| V-Strom250 | Front | A | ||

| V-Strom250 | Front | A1 | H-90 | |

| V-Strom250 | Rear | E | ||

| VZR1800 M109R | '06- | Front | A | /RN /R2 /RZ Limit. /R limit. |

| VZR1800 M109R | '06- | Front | A1 | H-100 /RN /R2 /RZ Limit. /R limit. |

| VZR1800 M109R | '06- | Rear | A | /RN /R2 /RZ Limit. /R limit. |

| VZR1800 M109R | Rear | A1 | H-100 /RN /R2 /RZ Limit. /R limit. | |

| VL1500LC /M90 | '09- | Front | A | |

| VL1500LC /M90 | '09- | Front | A1 | H-100 |

| VL1500LC /M90 | '09- | Rear | A | /RN /R2 /RZ Limit. /R limit. |

| VL1500LC /M90 | Rear | A1 | H-100 /RN /R2 /RZ Limit. /R limit. |

KAWASAKI

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| 1400GTR /ABS | '08- | Front | A | |

| 1400GTR /ABS | '08- | Front | A1 | H-100 |

| 1400GTR /ABS | '08- | Front | B | Ver.Light wight |

| 1400GTR /ABS | '08- | Rear | D | Specifications :hexagon castle nut |

| D-TRACKER /X | '07- | Front | A | |

| D-TRACKER /X | '07- | Front | A1 | H-90 |

| D-TRACKER /X | '08- | Rear | D | Specifications :hexagon castle nut |

| GPZ900R | Front | A | ||

| GPZ900R | Front | A1 | H-90 | |

| GPZ900R | Rear | A | ||

| GPZ900R | Rear | A1 | H-90 | |

| GPz1100 | '95-'97 | Front | A | |

| GPz1100 | '95-'97 | Front | A1 | H-90 |

| KL250 | '07-'16 | Front | A | |

| KL250 | '07-'16 | Front | A1 | H-90 |

| KLX250 | '08-'16 | Front | A | |

| KLX250 | '08-'16 | Front | A1 | H-90 |

| KLX250 | '08-'12 | Rear | D | Specifications :hexagon castle nut |

| NINJA250 /R | '08-'17 | Front | D | Specifications :hexagon castle nut |

| NINJA250 /R | '08-'17 | Rear | D | Specifications :hexagon castle nut |

| NINJA250 /R | '08-'17 | Pviot | S | |

| NINJA250 | '18- | Front | D | Specifications :hexagon castle nut |

| NINJA250 | '18- | Rear | D | Specifications :hexagon castle nut |

| NINJA250SL | -'17 | Front | D | Specifications :hexagon castle nut |

| NINJA250SL | -'17 | Rear | D | Specifications :hexagon castle nut |

| NINJA300 | -'17 | Front | D | Specifications :hexagon castle nut |

| NINJA300 | -'17 | Rear | D | Specifications :hexagon castle nut |

| NINJA300 | -'17 | Pviot | S | |

| NINJA400 | '18- | Front | D | Specifications :hexagon castle nut |

| NINJA400 | '18- | Rear | D | Specifications :hexagon castle nut |

| NINJA500 | '94-'09 | Rear | D | Specifications :hexagon castle nut |

| NINJA650/ABS | '17- | Front | A | |

| NINJA650/ABS | '17- | Front | A1 | |

| NINJA650/ABS | '17- | Rear | D | Specifications :hexagon castle nut |

| NINJA1000 | '11- | Front | A | |

| NINJA1000 | '11- | Front | A1 | H-90 |

| NINJA1000 | '11- | Pviot | S | |

| NINJA1000 | '11- | Rear | E | |

| NINJA H2/R (ZX1000NFF) | '15- | Front | B | |

| NINJA H2/R (ZX1000NFF) | '15- | Pviot | S | |

| NINJA H2/R (ZX1000NFF) | '16- | Pviot | S | |

| NINJA H2 SX/SE /SE+ /SX | '18- | Front | B | |

| NINJA H2 SX/SE /SE+ /SX | '18- | Pviot | S | |

| NINJA ZX-6R | 1998 | Front | A | |

| NINJA ZX-6R | 1998 | Front | A1 | H-100 |

| NINJA ZX-6R /RR | '98-'02 | Pviot | S | |

| NINJA ZX-6R /RR | 1998 | Rear | B | |

| NINJA ZX-6R /RR | '00-'04 | Front | A | |

| NINJA ZX-6R /RR | '00-'04 | Front | A1 | H-100 |

| NINJA ZX-6R /RR | '00-'04 | Front | B | Ver.Light wight |

| NINJA ZX-6R /RR | '00-'04 | Rear | D | Specifications :hexagon castle nut |

| NINJA ZX-6R /ABS/R | '05-'12 | Front | A | |

| NINJA ZX-6R /ABS/R | '05-'12 | Front | A1 | H-100 |

| NINJA ZX-6R /ABS | '05-'12 | Front | B | Ver.Light wight |

| NINJA ZX-6R /ABS | '08- | Pviot | S | |

| NINJA ZX-6R /ABS | '05-'12 | Rear | D | Specifications :hexagon castle nut |

| NINJA ZX-6R /ABS | '13- | Front | A | |

| NINJA ZX-6R /ABS | '13- | Front | A1 | H-100 |

| NINJA ZX-6R /ABS | '13- | Front | B | |

| NINJA ZX-6R /ABS | '13- | Rear | D | |

| NINJA ZX-7 /R /RR | '91-'03 | Front | A | |

| NINJA ZX-7 /R /RR | '91-'03 | Front | A1 | H-100 |

| NINJA ZX-7 /R /RR | '96-'03 | Pviot | S | |

| NNINJA ZX-7 /R /RR | '91-'03 | Rear | B | |

| NINJA ZX-9R | '00-'01 | Front | A | |

| NINJA ZX-9R | '00-'01 | Front | A1 | H-100 |

| NINJA ZX-9R | '00-'03 | Pviot | S | |

| NINJA ZX-9R | '00-'01 | Rear | D | Specifications :hexagon castle nut |

| NINJA ZX-9R | '02-'03 | Front | A | |

| NINJA ZX-9R | '02-'03 | Front | A1 | H-100 |

| NINJA ZX-9R | '02-'03 | Front | B | Ver.Light wight |

| NINJA ZX-10R | '04-'05 | Front | B | |

| NINJA ZX-10R /ABS | '08-'15 | Front | A | |

| NINJA ZX-10R /ABS | '08-'15 | Front | A1 | H-100 |

| NINJA ZX-10R /ABS | '08-'15 | Front | B | Ver.Light wight |

| NINJA ZX-10R /ABS | '08-'15 | Pviot | S | |

| NINJA ZX-10R /ABS | '06-'10 | Rear | D | Specifications :hexagon castle nut |

| NINJA ZX-10R /ABS | '11-'15 | Rear | D | Specifications :hexagon castle nut |

| NINJA ZX-10R /ABS | '16- | Front | B | |

| NINJA ZX-10R /ABS | '16- | Pviot | S | |

| NINJA ZX-10R /ABS | '16- | Rear | D | Specifications :hexagon castle nut |

| NINJA ZX-11 | '90-'93 | Front | A | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| NINJA ZX-11 | '90-'93 | Front | A1 | H-90 ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| NINJA ZX-11 | '90-'01 | Rear | E | |

| NINJA ZX-11 | '93-'01 | Front | A | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| NINJA ZX-11 | '93-'01 | Front | A1 | H-100 ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| NINJA ZX-12R | '00-'06 | Front | A | |

| NINJA ZX-12R | '00-'06 | Front | A1 | H-100 |

| NINJA ZX-12R | '00-'06 | Front | B | |

| NINJA ZX-12R | '00-'06 | Pviot | S | |

| NINJA ZX-12R | '00-'06 | Rear | D | Specifications :hexagon castle nut |

| NINJA ZX-14 /ABS/R ABS | '06- | Front | A | |

| NINJA ZX-14 /ABS/R ABS | '06- | Front | A1 | H-100 /R ABS |

| NINJA ZX-14 /ABS/R ABS | '06- | Front | B | Ver.Light wight |

| NINJA ZX-14 /ABS/R ABS | '12- | Pviot | S | |

| NINJA ZX-14 /ABS/R ABS | '06- | Rear | D | Specifications :hexagon castle nut |

| VERSYS | '08-'11 | Front | A | |

| VERSYS | '08-'11 | Front | A1 | H-90 |

| VERSYS | '12- | Pviot | S | |

| VERSYS 1000 /SE | '12- | Front | A | |

| VERSYS 1000 /SE | '12- | Front | A1 | |

| VERSYS 1000 | '12- | Front | B | |

| VERSYS 1000 /SE | '12- | Pviot | S | |

| VERSYS 1000 | '12-'18 | Rear | D | Specifications :hexagon castle nut |

| VERSYS 1000 /SE | '19- | Rear | D | Specifications :hexagon castle nut |

| W650 | '01-'08 | Front | A | |

| W650 | '01-'08 | Front | A1 | H-80 |

| W650 | '99-'08 | Rear | D | Specifications :hexagon castle nut |

| Z125PRO | '16- | Front | D | Specifications :hexagon castle nut |

| Z125PRO | '16- | Rear | D | Specifications :hexagon castle nut |

| Z250 | -'17 | Front | D | Specifications :hexagon castle nut |

| Z250 | -'17 | Rear | D | Specifications :hexagon castle nut |

| Z250 | -'17 | Pviot | A | |

| Z250SL | -'17 | Front | D | Specifications :hexagon castle nut |

| Z250SL | -'17 | Rear | D | Specifications :hexagon castle nut |

| Z650/ABS | '17- | Front | A | |

| Z650/ABS | '17- | Front | A1 | |

| Z650/ABS | '17- | Rear | D | |

| Z750FOUR | '76-'80 | Front | A | Z2 Z750-A4 /Z750-A5 |

| Z750FOUR | '73-'78 | Rear | B | Z2 Z750-A4 /Z750-A5 |

| Z750S | '05-'07 | Front | A | |

| Z750S | '05-'07 | Front | A1 | H-90 |

| Z800 | '13-'17 | Front | A | |

| Z800 | '13-'17 | Front | A1 | H-90 |

| Z800 | '13-'17 | Pviot | S | |

| Z800 | '13-'17 | Rear | D | Specifications :hexagon castle nut |

| Z900 | '72-'78 | Rear | B | Z1 /Z1A /Z1B /Z900-A4 /KZ900-A4 |

| Z900 | '18- | Front | A | |

| Z900 | '18- | Front | A1 | H-90 |

| Z900 | '18- | Pviot | S | |

| Z900 | '18- | Rear | D | Specifications :hexagon castle nut |

| Z1000 | '03-'09 | Front | A | |

| Z1000 | '03-'09 | Front | A1 | H-100 |

| Z1000 | '04-'06 | Rear | D | Specifications :hexagon castle nut |

| Z1000 | '07-'09 | Rear | D | Specifications :hexagon castle nut |

| Z1000 | '08- | Pviot | S | |

| Z1000 | '10-'16 | Front | A | |

| Z1000 | '10-'16 | Front | A1 | H-90 |

| Z1000 | '10-'16 | Rear | E | |

| Z1000 | '17- | Front | A | |

| Z1000 | '17- | Front | A1 | H-90 |

| Z1000 | '17- | Rear | E | |

| ZG1000 | '94-'06 | Front | A | |

| ZG1000 | '94-'06 | Front | A1 | H-90 |

| ZR250(BALIUS /BALIUSⅡ) | '91-'07 | Front | A | |

| ZR250(BALIUS /BALIUSⅡ) | '91-'07 | Front | A1 | H-80 |

| ZR250(BALIUS) | '91-'96 | Rear | D | Specifications :hexagon castle nut |

| ZR250(BALIUSⅡ) | '97-'07 | Rear | D | Specifications :hexagon castle nut |

| ZR7 /S | '00-'03 | Front | A | |

| ZR7 /S | '00-'03 | Front | A1 | H-90 |

| ZR750(Zephyr 750 ) | '91-'97 | Front | A | |

| ZR750(Zephyr 750 ) | '91-'97 | Front | A1 | H-90 |

| ZR750(Zephyr 750 ) | '91-'97 | Rear | A | |

| ZR750(Zephyr 750 ) | '91-'97 | Rear | A1 | H-90 |

| ZR1100(Zephyr 1100) | Front | A | ||

| ZR1100(Zephyr 1100) | Front | A1 | H-90 | |

| ZR1100(Zephyr 1100) | Rear | E | ||

| ZRX400 | '94-'08 | Front | A | |

| ZRX400 | '94-'08 | Front | A1 | H-90 |

| ZRX400 | '94-'08 | Rear | A | |

| ZRX400 | '94-'08 | Raer | A1 | H-90 |

| ZRX1100 /Ⅱ | '97-'00 | Front | A | |

| ZRX1100 /Ⅱ | '97-'00 | Front | A1 | H-100 |

| ZRX1100 /Ⅱ | '97-'00 | Pviot | S | |

| ZRX1100 /Ⅱ | '97-'00 | Rear | E | |

| ZRX1200 DEAG | '09- | Front | A | |

| ZRX1200 DEAG | '09- | Front | A1 | H-100 |

| ZRX1200 DEAG | '09- | Front | B | Ver.Light wight |

| ZRX1200 DEAG | '09- | Pviot | S | |

| ZRX1200 DEAG | '09- | Rear | E | |

| ZRX1200R /S | '01-'08 | Front | A | |

| ZRX1200R /S | '01-'08 | Front | A1 | H-100 |

| ZRX1200R /S | '01-'08 | Pviot | S | |

| ZRX1200R /S | '01-'08 | Rear | E | |

| ZX-6 | '90-'93 | Front | A | |

| ZX-6 | '90-'93 | Front | A1 | H-90 |

| ZX-10 | '88-'90 | Front | A | |

| ZX-10 | '88-'90 | Front | A1 | H-90 |

| ZX-10 | '88-'90 | Rear | E | |

| ZXR750R | '91-'94 | Front | A | |

| ZXR250 /R( ZX250-C,D ) | '91-'99 | Front | B | |

| ZXR250 /R( ZX250-C,D ) | '91-'99 | Rear | B | |

| ZXR750R | '91-'94 | Front | A1 | H-90 |

| ZXR750R | '91-'94 | Rear | B | |

| ZZR400 | '90-'92 | Front | A | |

| ZZR400 | '90-'92 | Front | A1 | H-90 |

| ZZR400 | '93-'07 | Front | A | |

| ZZR400 | '93-'07 | Front | A1 | H-90 |

| ZZR400 | '93-'07 | Rear | D | Specifications :hexagon castle nut |

| ZZR600 | '90-'05 | Front | A | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR600 | '90-'05 | Front | A1 | H-90 ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR600 | '90-'05 | Rear | D | Specifications :hexagon castle nut※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR600 | '05-'08 | Front | A | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR600 | '05-'08 | Front | A1 | H-100 ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR600 | '05-'08 | Front | B | Ver.Light wight ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR600 | '05-'08 | Pviot | S | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR600 | '05-'06 | Rear | D | Specifications :hexagon castle nut※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR1100 | '90-'93' | Front | A | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR1100 | '90-'93' | Front | A1 | H-90 ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR1100 | '90- | Rear | E | |

| ZZR1100 | '93- | Front | A | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR1100 | '93- | Front | A1 | H-100 ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| ZZR1200 | '02-'05 | Front | A | |

| ZZR1200 | '02-'05 | Front | A1 | H-100 |

| ZZR1200 | '02-'05 | Rear | D | Specifications :hexagon castle nut |

| ZZR1400 /ABS | '06- | Front | A | |

| ZZR1400 /ABS | '06- | Front | A1 | H-100 |

| ZZR1400 /ABS | '06- | Front | B | Ver.Light wight |

| ZZR1400 /ABS | '06- | Pviot | S | |

| ZZR1400 /ABS | '06- | Rear | D | Specifications :hexagon castle nut |

| ZZX1200 | '02-'05 | Front | A | |

| ZZX1200 | '02-'05 | Front | A1 | H-100 |

| ZZX1200 | '02-'05 | Rear | D | Specifications :hexagon castle nut |

BMW

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| C400 | Front | A | X/GT | |

| C400 | Front | A1 | H-90 | |

| C650 Sport | Front | A | ||

| C650 Sport | Front | A1 | H-90 | |

| C650GT | Front | A | ||

| C650GT | Front | A1 | H-90 | |

| C evolution | Front | A | ||

| C evolution | Front | A1 | H-90 | |

| F650CS | Front | A | ||

| F650CS | Front | A1 | H-90 | |

| F650GS(Single cylinder) | Front | A | ||

| F650GS(Single cylinder) | Front | A1 | H-80 | |

| F650GS(Single cylinder) | Rear | E | ||

| F650GS | Front | A | ||

| F650GS(Two cylinder) | Front | A1 | H-80 | |

| F650GS(Two cylinder) | Rear | E | ||

| F650GSDakar | '00- | Front | A | |

| F650GSDakar | '00- | Front | A1 | H-80 |

| F650GSDakar | '00- | Rear | E | |

| F650GSDakar | '04- | Front | A | |

| F650GSDakar | '04- | Front | A1 | H-80 |

| F650GSDakar | '04- | Rear | E | |

| F700GS | '12- | Front | A | |

| F700GS | '12- | Front | A1 | H-80 |

| F700GS | '12- | Rear | E | |

| F750GS | '18- | Front | B | T |

| F750GS | '18- | Rear | E | |

| F800GS | '10- | Front | A | |

| F800GS | '10- | Front | A1 | H-90 |

| F800GS | '10- | Rear | E | |

| F800GS | '12- | Front | A | |

| F800GS | '12- | Front | A1 | H-90 |

| F800GS | '12- | Rear | E | |

| F800GT | '13- | Front | A | |

| F800GT | '13- | Front | A1 | H-90 |

| F800R | '10-'14 | Front | A | |

| F800R | '10-'14 | Front | A1 | H-100 |

| F800R | '10-'14 | Rear | E | |

| F800R | '15- | Front | B | |

| F800R | '15- | Rear | E | |

| F800S /ST | Front | A | ||

| F800S /ST | Front | A1 | H-100 | |

| F850GS | '18- | Front | B | |

| F850GS | '18- | Rear/td> | E | |

| F900R | '20- | Front | B | |

| F900R | '20- | Rear | E | |

| F900XR | '20- | Front | B | |

| F900XR | '20- | Rear | E | |

| G310 | '17- | Front | B | /R /GS |

| G310 | '17- | Pviot | S | /R /GS |

| G310 | '17- | Rear | B | /R /GS |

| G650GS | '09- | Front | A | |

| G650GS | '09- | Front | A1 | H-80 |

| G650GS | '09- | Rea | E | |

| G650GS | '10- | Front | A | |

| G650GS | '10- | Front | A1 | H-80 |

| G650GS | '10- | Rear | E | |

| G650GS | '11- | Front | A | |

| G650GS | '11- | Front | A1 | H-80 |

| G650GS | '11- | Rear | E | |

| G650GS Sertao | '10- | Front | A | |

| G650GS Sertao | '10- | Front | A1 | H-80 |

| G650GS Sertao | '10- | Rear | E | |

| G650GS Sertao | '11- | Front | A | |

| G650GS Sertao | '11- | Front | A1 | H-80 |

| G650GS Sertao | '11- | Rear | E | |

| HP2 Sport | Front | B | ||

| HP2 Enduro | Front | A | ||

| HP2 Enduro | Front | A1 | H-100 | |

| HP2 Megamoto | Front | A | ||

| HP2 Megamoto | Front | A1 | H-100 | |

| K1 | Front | A | ||

| K1 | Front | A1 | H-100 | |

| K75 | '84-'95 | Front | A | /84/85/C./RT/S K569 |

| K75 | '84-'95 | Front | A1 | H-100 /84/85/C./RT/S K569 |

| K100 | '82-'91 | Front | A | /83/88/LT87/RS83/RT84 |

| K100 | '82-'91 | Front | A1 | H-100 /83/88/LT87/RS83/RT84 |

| K100 | Front | A | /RS | |

| K100 | Front | A1 | H-100 /RS | |

| K1100 | Front | A | /LT /RS | |

| K1100 | Front | A1 | H-100 /LT /RS | |

| K1200GT | Front/td> | A | ||

| K1200GT | Front | A1 | H-90 | |

| K1200GT | '05- | Front | A | |

| K1200GT | '05- | Front | A1 | H-100 |

| K1200LT | Front | A | ||

| K1200LT | Front | A1 | H-90 | |

| K1200R | Front | A | ||

| K1200R | Front | A1 | H-100 | |

| K1200RS | '97- | Front | A | |

| K1200RS | '97- | Front | A1 | H-90 |

| K1200R Sport | Front | A | ||

| K1200R Sport | Front | A1 | H-100 | |

| K1200S | Front | A | ||

| K1200S | Front | A1 | H-100 | |

| K1300GT | Front | A | ||

| K1300GT | Front | A1 | H-100 | |

| K1300R | Front | A | ||

| K1300R | Front | A1 | H-100 | |

| K1300S | Front | A | ||

| K1300S | Front | A1 | H-100 | |

| K1600 | Front | A | GT /GTL /BAGGER /GRAND AMRICA | |

| K1600 | Front | A1 | H-100 GT /GTL /BAGGER /GRAND AMRICA | |

| R50 | ---- | Front | A | Compatible with genuine product number No. 34111233490 |

| R50 | ---- | Front | A1 | H-80 Compatible with genuine product number No. 34111233490 |

| R50 | Rear/td> | A | /5 | |

| R50 | Rear | A1 | H-80 /5 | |

| R60 | '76-'82 | Front | A | /7/TIC |

| R60 | '76-'82 | Front | A1 | H-80/7/TIC |

| R60 | '76-'82 | Rear | A | /5/6/7/TIC |

| R60 | '76-'82 | Rear | A1 | H-80/5/6/7/TIC |

| R65 | '85-'92 | Front | A | /GS/RT SF |

| R65 | '85-'92 | Front | A1 | H-100 /GS/RT SF |

| R75 | '76-'79 | Front | A | H-80/7 |

| R75 | '76-'79 | Front | A1 | /7 |

| R75 | '76-'79 | Rear | A | /5/6/7 |

| R75 | '76-'79 | Rear | A1 | H-80/5/6/7 |

| R80 | '77-'84 | Front | A | /R/7/TIC |

| R80 | '77-'84 | Front | A1 | H-80/R/7/TIC |

| R80 | '77-'84 | Rear | A | /R/7/TIC |

| R80 | '77-'84 | REAR | A1 | H-80/R/7/TIC |

| R80 G/S,ST | '80-'87 | Front | A | |

| R80 G/S,ST | '80-'87 | Front | A1 | H-80 |

| R80 | '84-'95 | Front | A | /RT,/R,/Mystik |

| R80 | '84-'95 | Front | A1 | H-100/RT,/R,/Mystik |

| R80 GS | '87-'95 | Front | A | /GS,PD,/GS,PD(CH) |

| R80 GS | '87-'95 | Front | A1 | H-100 /GS PD /GS PD(CH) |

| R80R | '91-'96 | Front | A | /91,/Mystik94 |

| R80R | '91-'96 | Front | A1 | H-100 /91,/Mystik94 |

| R80GS Basic | 1996 | Front | A | |

| R80GS Basic | 1996 | Front | A1 | H-100 |

| R90 | '73-'76 | Front | A | /6,/S |

| R90 | '73-'76 | Front | A1 | H-80/6,/S |

| R90 | '73-'76 | REAR | A | /6,/S |

| R90 | '73-'76 | REAR | A1 | H-80/6,/S |

| R100 | '76-'84 | Front | A | /7,/7T,/T,CS,RS,RT,ST,IC |

| R100 | '76-'84 | Front | A1 | H-80 /7,/7T,/T,CR,SR,TS,TIC |

| R100 | '76-'84 | REAR | A | /7,/7T,/T,CS,RS,RT,S,TIC (Drum brake) |

| R100 | '76-'84 | REAR | A1 | H-80 /7,/7T,/T,CS,RS,RT,S,TIC (Drum brake) |

| R100 | '76-'84 | REAR | A | /7,/7T,/T,CS,RS,RT,S,TIC (Disk brake) |

| R100 | '76-'84 | REAR | A1 | H-80 /7,/7T,/T,CS,RS,RT,S,TIC (Disk brake) |

| R100 | '86-'96 | Front | A | RS,/RT,/GS,/GS, PD,/R91, /R Mystik94 |

| R100 | '86-'96 | Front | A1 | H-100 RS,/RT,/GS,/GS, PD,/R91, /R Mystik94 |

| R850 | '94- | Front | A | /C /GS /R /RT |

| R850 | '94- | Front | A1 | H-90 /C /GS /R /RT |

| R1100 | '94- | Front | A | /GS /R /RS /RT /S |

| R1100 | '94- | Front | A1 | H-90 /GS /R /RS /RT /S |

| R1150 | Front | A | GS /GS-A /R /R Rockster /RT /RS | |

| R1150 | Front | A1 | H-90 GS /GS-A /R /R Rockster /RT /RS | |

| R1200C | Front | A | ||

| R1200C | Front | A1 | H-90 | |

| R1200CL | Front | A | ||

| R1200CL | Front | A1 | H-90 | |

| R1200C Montauk | Front | A | ||

| R1200C Montauk | Front | A1 | H-90 | |

| R1200GS | '04-'12 | Front | B | |

| R1200GS | '13- | Front | A | |

| R1200GS | '13-'18 | Front | A1 | H-90 |

| R1200GS-A | '06-'13 | Front | B | |

| R1200GS-A | '14-'19 | Front | A | |

| R1200GS-A | '14-'19 | Front | A1 | H-90 |

| R1200R | '06-'14 | Front | B | |

| R1200R | '15-'19 | Front | B | |

| R1200RS | '15-'19 | Front | B | |

| R1200RT | '05-'13 | Front | B | |

| R1200RT | '14-'18 | Front | A | |

| R1200RT | '14-'18 | Front | A1 | H-90 |

| R1200S /ST | Front | B | ||

| R1250GS | '18- | Front | A | |

| R1250GS | '18- | Front | A1 | H-90 |

| R1250GS-A | '19- | Front | A | |

| R1250GS-A | '19- | Front | A1 | H-90 |

| R1250R | '19- | Front | B | |

| R1250RS | '19- | Front | B | |

| R1250RT | '18- | Front | A | |

| R1250RT | '18- | Front | A1 | H-90 |

| R nineT | '14-'16 | Front | A | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| R nineT | '14-'16 | Front | A1 | H-100 ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| R nineT | '16- | Front | B | ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| R nineT Scrambler | '16- | Front | B | Pure,Racer,Urban G/S |

| S1000R | '13- | Front | A | |

| S1000R | '13- | Front | S1 | H-100 |

| S1000R | '13- | Front | B | Ver.Light wight |

| S1000R | '13- | Pviot | S | |

| S1000R | '13- | Pviot | S | H-100 |

| S1000R | '13- | Rear | E | |

| S1000RR | '10- | Front | A | |

| S1000RR | '10- | Front | A1 | H-100 |

| S1000RR | '10- | Front | B | |

| S1000RR | '10-'12 | Pviot | S | |

| S1000RR | '10- | Rear | E | |

| S1000RR | '13- | Pviot | S | |

| S1000XR | '15- | Front | B | |

| S1000XR | '15- | Pviot | S | |

| S1000XR | '15- | Pviot | S1 | H-100 |

| S1000XR | '15- | Rear | E |

HARLEY

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| 1200X (LD) | 2012 | Front | B | XLR |

| BAD BOY | '95-'96 | Front | B | FXSTSB |

| BLACKLINE 96,103 | '11-'13 | Front | B | FXS |

| BLACKLINE 96,103 | '11-'13 | Rear | B | FXS |

| BREAKOUT /114 | '18-'20 | Front | B | FXBR /FXBRS |

| BREAKOUT /114 | '18-'20 | Rear | B | FXBR /FXBRS |

| Conv Low Rider | '91-'92 | Front | B | FXRS |

| Conv Low Rider | '91-'92 | Rear | B | FXRS |

| CVO103TM | 2014 | Front | B | FLHTK |

| CVO ANN ULTRA CLASSIC ELECTRA GLIDE | 2013 | Front | B | FLHTCUSE8 /FLHTCU8 |

| CVO BREAKOUT | '13-'14 | Front | B | FXSBSE |

| CVO BREAKOUT | '13-'14 | Rear | B | FXSBSE |

| CVO DYNA FAT BOB | 2009 | Front | B | FXDF |

| CVO DYNA FAT BOB | 2009 | Rear | B | FXDF |

| CVO ELECTRA GLIDE | '04-'05 | Front | B | FLHTCSE |

| CVO FAT BOY | 2010 | Front | B | FXDFSE |

| CVO FAT BOY | 2010 | Rear | B | FXDFSE |

| CVO LIMITED 110TM | '14-'17 | Front | B | FLHTKSE |

| CVO LIMITED MILWAUKEE EIGHT | 2019 | Front | B | FLHTKSE |

| CVO ROAD GLIDE | '00-'01 | Front | B | FLTRSEI |

| CVO ROAD GLIDE | '09-'19 | Front | B | FLTRUSE /FLTRXSE2 FLTRXSE3 |

| CVO ROAD KING | '13-'14 | Front | B | FLHRSE5 /FLHR /FLHRSE |

| CVO SOFTAIL | '10-'15 | Front | B | FLSTSE /FLSTSE 2 FLSTSE 3 /FLSTNSE |

| CVO SOFTAIL SPRINGER | 2009 | Front | B | FXSTSSE3 |

| CVO SOFTAIL SPRINGER | 2009 | Rear | B | FXSTSSE3 |

| CVO STREET GLIDE | '10-'20 | Front | B | FLHXSE /FLHXSE 2 FLHXSE 3 |

| CVO ULTRA CLASSIC ELECTRA GLIDE | '09-'13 | Front | B | FLHTCUSE4 /FLHTCUSE5 /FLHTCUSE8 /FLHTCU8 |

| DELUXE | '18-'20' | Front | B | FLDE |

| DELUXE | '18-'20 | Rear | B | FLDE |

| DYNA CONVERTIBLE | '94-99' | Front | B | FXDS-CON /FXDX |

| DYNA CONVERTIBLE | '94-'02 | Rear | B | FXDS-CON /FXDX |

| DYNA Daytona | '91-'92 | Front | B | FXDB-S |

| DYNA Daytona | '91-'92 | Rear | B | FXDB-S |

| DYNA GLIDE CONVERTIBLE | 1997 | Front | B | FXDS |

| DYNA GLIDE CONVERTIBLE | 1997 | Rear | B | FXDS |

| DYNA CONVERTIBLE | '00-'02 | Front | B | FXDS-CON /FXDX |

| DYNA FAT BOB | 2009 | Front | B | FXDF |

| DYNA FAT BOB | 2009 | Rear | B | FXDF |

| DYNA LOW RIDER | '93-'99 | Front | B | FXDL |

| DYNA LOW RIDER | '93-'99 | Rear | B | FXDL |

| DYNA LOW RIDER | '00-'03 | Front | B | FXDL |

| DYNA LOW RIDER | '00-'03 | Rear | B | FXDL |

| DYNA LOW RIDER | '06-'07 | Front | B | FXDL /FXDLI |

| DYNA LOW RIDER | '06-'07 | Rear | B | FXDL /FXDLI |

| DYNA LOW RIDER | '08-'17 | Front | B | FXDL |

| DYNA LOW RIDER | '08-'17 | Rear | B | FXDL |

| DYNA POLICE | '01-'03 | Front | B | FXDP |

| DYNA POLICE | '01-'03 | Rear | B | FXDP |

| DYNA STREET BOB | '06-'07 | Front | B | FXDB /FXDBI |

| DYNA STREET BOB | '06-'07 | Rear | B | FXDB /FXDBI |

| DYNA STREET BOB | '10-'17 | Front | B | FXDBP /FXDB /FXDBA /FXDBB /FXDBC |

| DYNA STREET BOB | '10-'17 | Rear | B | FXDBP /FXDB /FXDBA /FXDBB /FXDBC |

| DYNA SUPER GLIDE | '97-'99 | Front | B | FXD /FXDS-CON |

| DYNA SUPER GLIDE | '97-'99 | Rear | B | FXD /FXDS-CON |

| DYNA SUPER GLIDE | '00-'03 | Front | B | FXDX /FXD /FXDXT |

| DYNA SUPER GLIDE | '00-'05 | Rear | B | FXDX /FXD /FXDXT /FXDWG /FXDI /FXDX1 /FXDC /FXDCI |

| DYNA SUPER GLIDE | '06-'07 | Front | B | FXD /FXD35 /FXDI |

| DYNA SUPER GLIDE | '06-'07 | Rear | B | FXD /FXD35 /FXDI |

| DYNA SUPER GLIDE | '08-'14 | Front | B | FXDC /FXD |

| DYNA SUPER GLIDE | '08-'14 | Rear | B | FXDC /FXD |

| DYNA SUPER WIDE CUSTOM | 2006 | Front | B | FXDCI |

| DYNA SUPER WIDE CUSTOM | 2006 | Rear | B | FXDCI |

| DYNA SWITCHBACK | '12-'16 | Front | B | FLD |

| DYNA SWITCHBACK | '12-'16 | Rear | B | FLD |

| DYNA WIDE GLIDE | '93-'05 | Front | B | FXDWG /FXDWGI |

| DYNA WIDE GLIDE | '93-'99 | Rear | B | FXDWG /FXDWGI |

| DYNA WIDE GLIDE | '01-'03 | Front | B | FXDWG2 /FXDXT |

| DYNA WIDE GLIDE | '00-'05 | Rear | B | FXWDG /FXDWG2 /FXDWG /FXDXT /FXDWGI |

| DYNA WIDE GLIDE | '11-'17 | Front | B | FXDWG |

| DYNA WIDE GLIDE | '11-'17 | Rear | B | FXDWG |

| ELECTRIA GLID /Classic /Sport /STD /ULTRA | '91-'99 | Front | B | FLHS /FLHTC /FLHTCU /FLHTC-I /FLHTC-U |

| ELECTRIA GLID /Classic /Sport /STD /ULTRA | '92-'99 | Rear | B | FLHS /FLHTC /FLHTCU /FLHTC-I /FLHTC-U |

| ELECTRA GLIDE | '03-'07 | Front | B | FLHT /FLHTC /FLHTCI /FLHTI |

| ELECTRA GLIDE | '08-'20 | Front | B | FLHTC /FLHT /FLHTK /FLHTP /FLHTC96 /FLHT103 /FLHTCUTC /FLHTCUL |

| FAT BOB | 2008 | Front | B | FXDF |

| FAT BOB | 2008 | Rear | B | FXDF |

| FAT BOB | '18-'20 | Front | B | FXFB /FXFBS |

| FAT BOB | '18-'20 | Rear | B | FXFB /FXFBS |

| FAT BOY | '91-'96 | Front | B | FLSTF |

| FAT BOY | '91-'96 | Rear | B | FLSTF |

| FAT BOY /S | '08-'20 | Front | B | FLSTF /FLSTFBS |

| FAT BOY /S | '08-'20 | Rear | B | FLSTF /FLSTFBS |

| FAT BOY | 2009 | Front | B | FXDF |

| FAT BOY | 2009 | Rear | B | FLSTF |

| FAT BOY /114 /ANV | '18-'19 | Front | B | FLFB /FLFBS |

| FAT BOY /114 /ANV | '18-'19 | Rear | B | FLFB /FLFBS |

| FLSTFSE2 /INTERNATIONAL | 2006 | Front | B | FLST |

| FXR-2 /FXR-3 | 1999 | Front | B | FXR-2 /FXR-3 |

| FXR-2 /FXR-3 | 1999 | Rear | B | FXR-2 /FXR-3 |

| HERITAGE | 2006 | Front | B | FLST /FLSTI |

| HERITAGE | 2006 | Rear | B | FLST /FLSTI |

| HERITAGE CLASSIC | '93-'96 | Front | B | FLSTC |

| HERITAGE CLASSIC | '93-'96 | Rear | B | FLSTC |

| HERITAGE CLASSIC /114 | '18-'20 | Front | B | FLHC /FLHCS |

| HERITAGE CLASSIC /114 | '18-'20 | Rear | B | FLHC /FLHCS |

| HERITAGE SHRINE | 2012 | >Front | B | FLSTC |

| HERITAGE SOFTAIL Classic | '91-'92 | Front | B | FLSTC |

| HERITAGE SOFTAIL Classic | '91-'92 | Rear | B | FLSTC |

| HERITAGE SPECIAL NOSTALGIA | '93-'06 | Front | B | FLSTN /FLSTNI |

| HERITAGE SPECIAL NOSTALGIA | '93-'06 | Rear | B | FLSTN /FLSTNI |

| LOW RIDER /Custom /Sport | '91-'94 | Front | B | FXLR /FXRS /FXRS-SP |

| LOW RIDER /Custom /Sport | '91-'94 | Rear | B | FXLR /FXRS /FXRS-SP |

| LOW RIDER | '18-'19 | Rear | B | FXLR |

| NIGHT ROD | '08-'17 | Front | B | VRSCD /VRSCDX /VRSCDXA VRSCDA |

| NIGHT TRAIN | '08-'09 | Front | B | FXSTB |

| NIGHT TRAIN | '08-'09 | Rear | B | FXSTB |

| POLICE | '11-'14 | Front | B | FLHP /FLHPE FLHTP |

| POLICE ELECTRA GLIDE STANDARD | 2003 | Front | B | FLHPI /FLHTPI |

| POLICE ROAD KING | 2003 | Front | B | FLHPEI |

| PRO STREET BREAKOUT | 2017 | Front | B | FXSE |

| REVOLUTION X 500 /X750 | '15-'17 | Front | B | NA /NB |

| REVOLUTION X 500 /X750 | '15-'17 | Rear | B | NA /NB |

| ROAD GLIDE /CLASSIC | '98-'99 | Front | B | FLTR /FLTRC-I /FLTR-I |

| ROAD GLIDE /CLASSIC | '98-'99 | Rear | B | FLTR /FLTRC-I /FLTR-I |

| ROAD GLIDE | '03-'07 | Front | B | FLTR /FLTRI |

| ROAD GLIDE | '08-'20 | Front | B | FLTR /FLTRX /FLTRX96 /FLTR103 /FLTRU /FLTRXS |

| ROAD KING /CLASSIC | '94-'99 | Front | B | FLHR /FLHR-I /FLHRCI /FLHRI |

| ROAD KING /CLASSIC | '94-'99 | Rear | B | FLHR /FLHR-I /FLHRCI /FLHRI |

| ROAD KING | '03-'07 | Front | B | FLHR /FLHRI /FLHRC /FLHRCI /FLHRS /FLHRSI |

| ROAD KING /CLASSIC /SPECIAL | '08-'20 | Front | B | FLHR /FLHRC /FLHRS /FLHR96 /FLHR103 FLHRC96 /FLHRC103/FLHRXS |

| SCREAMIN EAGLE SPRINGER SOFTAIL | '07-'08 | Front | B | FXSTSSE /FXSTSSE 2 |

| SCREAMIN EAGLE SPRINGER SOFTAIL | 2008 | Rear | B | FXSTSSE 2 |

| Screamin' Eagle | 2008 | Front | B | FLHTCUSE3 /FLHRSE4 |

| SCREAMING EAGLE | 2000 | Front | B | FLHRSEI |

| SHRINE | '11-'13 | Front | B | FLSTF /FLSTC |

| SOFTAIL | 2005 | Front | B | FLSTC /FLSTF /FLSTFI /FLSTN /FLSTNI /FXSTC |

| SOFTAIL | 2005 | Front | B | FXST /FXSTB /FXSTI /FXSTBI |

| SOFTAIL | 2005 | Front | B | FXSTSI |

| SOFTAIL | 2005 | Rear | B | FLSTC /FLSTF /FLSTFI /FLSTN /FLSTNI /FXSTC /FXSTSI |

| SOFTAIL BAD BOY | 1997 | Front | B | FXSTSB |

| SOFTAIL BAD BOY | 1997 | Rear | B | FXSTSB |

| SOFTAIL BREAKOUT /114 /ANV | 2018 | Front | B | FXBR /FXBRS |

| SOFTAIL BREAKOUT | '13-'17 | Rear | B | FXSB |

| SOFTAIL BREAKOUT /114 /ANV | 2018 | Front | B | FXBR /FXBRS |

| SOFTAIL BREAKOUT /114 /ANV | 2018 | Rear | B | FXBR /FXBRS |

| SOFTAIL CROSS BONES | '08-'11 | Front | B | FLSTSB |

| SOFTAIL CROSS BONES | '08-'11 | Rear | B | FLSTSB |

| SOFTAIL Custom | '91-'99 | Front | B | FXSTC |

| SOFTAIL Custom | '91-'99 | Rear | B | FXSTC |

| SOFTAIL CUSTOM | '07-'10 | Front | B | FXSTC |

| SOFTAIL CUSTOM | '08-'10 | Rear | B | FXSTC |

| SOFTAIL DELUXE | '07-'17 | Front | B | FLSTN |

| SOFTAIL DELUXE | '08-'17 | Rear | B | FLSTN |

| SOFTAIL DELUXE | 2018 | Front | B | FLDE |

| SOFTAIL DELUXE | 2018 | Rear | B | FLDE |

| SOFTAIL FAT BOB /114 | 2018 | Front | B | FXFB /FXFBS |

| SOFTAIL FAT BOB /114 | 2018 | Rear | B | FXFB /FXFBS |

| SOFTAIL FAT BOY | '97-'06 | Front | B | FLSTF /FLSTFI |

| SOFTAIL FAT BOY | '97-'06 | Rear | B | FLSTF /FLSTFI |

| SOFTAIL FAT BOY | '10-'17 | Front | B | FLSTFB |

| SOFTAIL FAT BOY | '10-'17 | Rear | B | FXSTB |

| SOFTAIL FXDR TM114 | 2019 | Front | B | FXDRS |

| SOFTAIL HERITAGE CLASSIC | '97-'99 | Front | B | FLSTC /FLSTCI |

| SOFTAIL HERITAGE CLASSIC | '01-'06 | Front | B | FLSTC /FLSTCI |

| SOFTAIL HERITAGE CLASSIC | 2000 | Front | B | FXSTS |

| SOFTAIL HERITAGE CLASSIC | '97-'06 | Rear | B | FLSTC /FLSTCI /FXSTS |

| SOFTAIL HERITAGE CLASSIC | '07-'17 | Front | B | FLSTC /FLST |

| SOFTAIL HERITAGE CLASSIC | '08-'17 | Rear | B | FLSTC /FLST |

| SOFTAIL HERITAGE CLASSIC /114 /ANV | 2018 | Front | B | FLHC /FLHCS |

| SOFTAIL HERITAGE CLASSIC /114 /ANV | 2018 | Rear | B | FLHC /FLHCS |

| SOFTAIL LOW RIDER S | 2020 | Front | B | FXLRS |

| SOFTAIL LOW RIDER S | 2020 | Rear | B | FXLRS |

| SOFTAIL NIGHT TRAIN | '00-'06 | Front | B | FLSTB /FLSTBI |

| SOFTAIL NIGHT TRAIN | '00-'06 | Rear | B | FLSTB /FLSTBI |

| SOFTAIL NIGHT TRAIN | 2007 | Front | B | FXSTB |

| SOFTAIL SHRINE | 2007 | Front | B | FLSTC /FLSTF |

| SOFTAIL SLIM | '12-'17 | Front | B | FLS /FLSS |

| SOFTAIL SLIM | '12-'17 | Rear | B | FLS /FLSS |

| SOFTAIL SLIM | '18-'20 | Front | B | FLSL |

| SOFTAIL SLIM | '18-'20 | Rear | B | FLSL |

| SOFTAIL SPORT GLIDE | 2018 | Front | B | FLHC /FLHCS |

| SOFTAIL SPORT GLIDE | 2018 | Rear | B | FLHC |

| SOFTAIL SPRINGER | '93-'99 | Front | B | FXSTS |

| SOFTAIL SPRINGER | '93-'99 | Rear | B | FXSTS |

| SOFTAIL SPRINGER | '01-'06 | Front | B | FXSTS |

| SOFTAIL SPRINGER | '01-'06 | Rear | B | FXSTS |

| SOFTAIL STANDARD | '03-'06 | Front | B | FXST /FXSTI |

| SOFTAIL STANDARD | '03-'06 | Rear | B | FXST /FXSTI |

| SOFTAIL STD | '00-'04 | Front | B | FXST /FXSTI |

| SOFTAIL STD | '00-'04 | Rear | B | FXST /FXSTI |

| SOFTAIL STD | '07-'15 | Front | B | FXST |

| SOFTAIL STD | '08-'15 | Rear | B | FXST |

| SPORT GLIDE | '91-'94 | Front | B | FXR /FXRT /FXRTS-CON |

| SPORT GLIDE | '91-'94 | Rear | B | FXR /FXRT /FXRTS-CON |

| SPORT GLIDE | '18-'20 | Front | B | FLSB |

| SPORT GLIDE | '18-'20 | Rear | B | FLSB |

| SPORTSTER | '91-'99 | Front | B | XL1200 /XLH883 /XLH1200 |

| SPORTSTER /XL883 /XL1200 | '00-'07 | Front | B | XLH /XL /XLHC1200 /XLHS1200 |

| SPORTSTER /XL883 /XL1200 | '08-'17 | Rear | B | XLH /XL /XLHC1200 /XLHS1200 ※Not XLR 1200X除く |

| SPORTSTER /XL883 /XL1200 | '11-'20 | Front | B | XLH /XL /XLHC1200 /XLHS1200※Since there are multiple types, it is necessary to confirm the genuine product number. |

| SPORTSTER /XL883 /XL1200 | '08-'20 | Front | B | XLH /XL /XLHC1200 /XLHS1200※Since there are multiple types, it is necessary to confirm the genuine product number. |

| SPORTSTER XL883N /XL883R | '14-'20 | Front | B | XL883N /XL883R ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| SPORTSTER XL1200NS /XL1200V | '14-'20 | Front | B | XL1200NS /XL1200V ※Since there are multiple types, it is necessary to confirm the genuine product number. |

| SPORTSTER | '08-'10 | Front | B | XR |

| Springer SOFTAIL | '91-'92 | Front | B | FXSTS |

| Springer SOFTAIL | '91-'92 | Rear | B | FXSTS |

| STREET BOB | '08-'09 | Front | B | FXDB |

| STREET BOB | '08-'09 | Rear | B | FXDB |

| STREET BOB | '18-'19 | Rear | B | FXDB |

| SUPER GLIDE | '91-'96 | Front | B | FXR /FXD /FXR-2 /FXR3 /FXRS-CON |

| SUPER GLIDE | '95-'96 | Rear | B | FXD |

| SUPER GLIDE | 2002 | Front | B | FXD /FXDXT |

| SUPER GLIDE | 2007 | Front | B | FXDC |

| SUPER GLIDE | 2007 | Rear | B | FXDC |

| SUPER GLIDE /SPECIAL | 2019 | Front | B | FLHX /FLHXS |

| STREET 500 | '19-'20 | Front | B | XG500 |

| STREET 500 | '19-'20 | Rear | B | XG500 |

| STREET 750 | '15-'20 | Front | B | XG750 |

| STREET 750 /ROD | '15-'20 | Rear | B | XG750 /XG750A |

| STREET GLIDE | '06-'07 | Front | B | FLHX /FLHXI |

| STREET GLIDE | '08-'20 | Front | B | FLHX /FLHX103 FLHX96 FLHXS |

| Tour Glide /Classic /Ultra Classic | '91-'96 | Front | B | FLTC /FLTCU /FLTC-U /FLTCU-I |

| Tour Glide /Classic /Ultra Classic | '92-'96 | Rear | B | FLTC /FLTCU /FLTC-U /FLTCU-I |

| TOURING ELECTRA GLIDE | '00-'02 | Front | B | FLHT /FLHTC /FLHTC-I |

| TOURING ROAD KING | '00-'02 | Front | B | FLHR /FLHRI |

| TOURING ROAD GLIDE | '00-'02 | Front | B | FLTR /FLTR-I /FLHRC-I |

| TOURING ULTRA CLASSIC ELECTRA GLIDE | '00-'01 | Front | B | FLHTCU-I |

| ULTRA CLASSIC ELECTRA GLIDE | '93-'99 | Front | B | FLHTC-U /FLHTCU-I |

| ULTRA CLASSIC ELECTRA GLIDE | '93-'99 | Rear | B | FLHTC-U /FLHTCU-I |

| ULTRA CLASSIC ELECTRA GLIDE | '03-'07 | Front | B | FLHTCU /FLHTCUI |

| ULTRA /CLASSIC /LIMITED | '08-'20 | Front | B | FLHTCU /FLHTCU96 /FLHTCU103 /FLHTCUSE6 /FLHTCUSE7 FLHTKL |

| V-ROD | '08-'17 | Front | B | VRSCAW /VRSCAWA /VRSCF /VRSCDX |

| WIDE GLIDE | 2008 | Front | B | FXDWG |

| WIDE GLIDE | 2008 | Rear | B | FXDWG |

| WIDE GLIDE | 2008 | Rear/td> | B | FXDWG |

TRIUMPH

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| Bonneville | '01-'15 | Front | A | /T100 /SE EFI /carburet |

| Bonneville | '01-'15 | Front | A1 | H-90 |

| Bonneville | '01-'15 | Rear | E | |

| Bonneville T-120 | '16- | Front | A | |

| Bonneville T-120 | '16- | Front | A1 | H-90 |

| Bonneville T-120 | '16- | Rear | E | |

| Bonneville Bobber | '17- | Front | A | |

| Bonneville Bobber | '16- | Front | A1 | H-90 |

| Bonneville Bobber | '16- | Rear | E | |

| Daytona675 | Front | A | ||

| Daytona675 | Front | A1 | H-90 | |

| Daytona675 | Pviot | S | ||

| Daytona675 | Rear | E | ||

| RocketⅢ | Front | A | /Classic /Classic Rosdster | |

| RocketⅢ | Front | A1 | H-100 /Classic /Classic Rosdster | |

| Scrambler | '01- | Front | A | EFI /carburet |

| Scrambler | '01- | Front | A1 | H-90 EFI /carburet |

| Scrambler | '01- | Rear | E | EFI/carburet |

| Speed Master | Front | A | EFI Front Wheel 469050 GT | |

| Speed Master | Front | A1 | H-100 EFI Front Wheel 469050 GT | |

| Speed Triple | Front | A | VIN :210445 to 461331 | |

| Speed Triple | Front | A1 | H-100 VIN :210445 to 461331 | |

| Speed Triple | Front | A | From VIN :4613321 | |

| Speed Triple | Front | A1 | H-90 From VIN :4613321 | |

| Spped Twin | Front | A | ||

| Spped Twin | Front | A1 | H-90 | |

| Spped Twin | Rear | E | ||

| Street Cup | Front | A | ||

| Street Cup | Front | A1 | ||

| Street Cup | Rear | E | ||

| Street Triple 675 | '08-'16 | Front | A | /R |

| Street Triple675 | '08-'16 | Front | A1 | H-90 /R |

| Street Triple675 | '08-'16 | Pviot | S | |

| Street Triple675 | '08-'16 | Rear | E | |

| Street Twin | Front | A | ||

| Street Twin | Front | A1 | H-90 | |

| Street Twin | Rear | E | ||

| Street Scrambler | Front | A | ||

| Street Scrambler | Front | A1 | H-90 | |

| Street Scrambler | Rear | E | ||

| Tiger800 | Front | A | /XRx /XCx /XC | |

| Tiger800 | Front | A1 | H-90 /XRx /XCx /XC | |

| Tiger800 | Pviot | S | ||

| Tiger800 | Rear | E | ||

| Tiger1050 | Front | A | ||

| Tiger1050 | Front | A1 | H-100 | |

| Tiger Exp. | Front | A | ||

| Tiger Exp. | Front | A1 | H-90 | |

| Tiger Sports | Front | A | VIN :570059 | |

| Tiger Sports | Front | A1 | H-100 VIN :570059 | |

| Thruxton900 | '00-'15 | Front | A | |

| Thruxton900 | '00-'15 | Front | A1 | EFI /carburet H-90 |

| Thruxton900 | '00-'15 | Rear | E | |

| Thruxton /R | '16- | Front | A | |

| Thruxton /R | '16- | Front | A1 | H-90 |

| Thruxton /R | '16- | Rear | E | |

| Thunderbird | Front | A | /1600 /1700 | |

| Thunderbird | Front | A1 | H-100 /1600 /1700 | |

| Trophy 1215 | Front | A | /SE | |

| Trophy 1215 | Front | A1 | H-90 /SE |

DUCATI

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| Desmosedici RR | '08-'08 | Front | B | |

| Diavel | '11- | Front | B | /Strada/Cromo/Carbon |

| Hyper Motard | '08-'12 | Front | B | 796/1100/1100 S/1100 EVO/1100 EVO SP |

| Hyper Motard | '13- | Front | B | 821 /SP /Hyperstrada /HyperStrada 939 |

| MH900e | 2001 | Front | B | |

| MONSTER 400 | '95-'97 | Front | B | / DARK/Metallic |

| MONSTER 400 | '00-'02 | Front | B | |

| MONSTER 400 | '05-'08 | Front | B | Compatible with genuine product number No. 81910781AA |

| MONSTER 600 | '93-'99 | Front | B | / DARK/DARK CITY/Metallic |

| MONSTER 600 | '00-'01 | Front | B | |

| MONSTER 620 | '02-'04 | Front | B | /DARK |

| MONSTER 620 | '05-'06 | Front | B | Compatible with genuine product number No. 81910781AA |

| MONSTER 659 | '11-'14 | Front | B | Compatible with genuine product number No. 81910781AA |

| MONSTER 695 | '07-'08 | >Front | B | /ABS |

| MONSTER 696 | '08-'14 | Front | B | /ABS /ANINVERSARY |

| MONSTER 696 | '08-'14 | Rear | B | /ABS /ANINVERSARY |

| MONSTER 750 | '96-'99 | Front | B | /DARK /CITY /DRAK CITY |

| MONSTER 750 | '00-'02 | Front> | B | |

| MONSTER 795 | '12-'14 | Front | B | /ABS |

| MONSTER 796 | '11- | Front | B | /Anniversary/ABS |

| MONSTER 797 | '17- | Front | B | |

| MONSTER 797 | '17- | Rear | B | |

| MONSTER 800 | '00-'03 | Front | B | |

| MONSTER 821 | '15- | Front | B | / DARK / Stripe |

| MONSTER 821 | '15- | Rear | B | |

| MONSTER 900 | '93-'99 | Front | B | / DARK/CROMO/Metallic /S /CITY /DRAK CITY |

| MONSTER 900 | '00-'01 | Front | B | |

| MONSTER 900s | '00-'01 | Front | B | |

| MONSTER 1000 | '03-'05 | Front | B | |

| MONSTER 1000s | 2005 | Front | B | |

| Monster 1100 Diesel | '12- | Front | B | |

| Monster 1100 | '08- | Front | B | EVO /Anniversary/ABS/S |

| Monster 1200 | '14- | Front | B | /S /R |

| MONSTER S2R 800/ DARK | '05-'07 | Front | B | Compatible with genuine product number No.81910781AA |

| MONSTER S2R 1000 | '06-'08 | Front | B | |

| MONSTER S4 | '01-'04 | Front | B | /R/ABS |

| MONSTER S4R | '05-'06 | Front | B | |

| MONSTER S4R | '07-'08 | Front | B | |

| Monster S4RS | '06-'08 | Front | B | /Tricolore |

| Multistrada 620 | 2006 | Front | B | / DARK |

| Multistrada 950 | '17- | Front | B | |

| Multistrada 1000 | '03-'06 | Front | B | /S |

| Multistrada 1100 | '07-'09 | Front | B | /S |

| Multistrada 1200 | '10- | Front | B | S Touring/Pinks peak/GT/S Sport/ABS /S Pikes Peak/Granturismo |

| Panigale V4 | '17- | Front | B | |

| Scrambler | '15- | Front | B | Icon /Urban Enduro /Classic /Full Throttle /CafeRacer |

| Scrambler | '17- | Front | B | /Desert Sled |

| Scrambler | '17- | Rear | B | /Desert Sled /CafeRacer |

| Sport Classic | '06-'10 | Front | B | GT1000/Touring/Sport1000/Sport1000 SP/Sport1000 Single-SE |

| SPORTTOURING ST2 | '00-'03 | Front | B | |

| SPORTTOURING ST3 | '04-'05 | Front | B | |

| SPORTTOURING ST3s | '06-'07 | Front | B | |

| SPORTTOURING ST3s ABS | '06-'07 | Front | B | |

| SPORTTOURING ST4 | '00-'03 | Front | B | |

| SPORTTOURING ST4s | '02-'05 | Front | B | /ABS |

| Street Fighter | '10- | Front | B | /S |

| Street Fighter 848 | '12- | Front | B | |

| Super Bike 748 | '00-'03 | Front | B | /R/S |

| SuperBike 749 | '03-'06 | Front | B | S/R/Dark |

| SuperBike 749 | '03-'06 | Rear | B | |

| SuperBike 848 | '08- | Front | B | EVO/Corse SE |

| SuperBike 888 | '94-'95 | Front | B | |

| SuperBike 899 | Front | B | Panigale | |

| SuperBike 899 | Rear | B | ||

| SuperBike 959 | Front | B | Panigale | |

| SuperBike 959 | Rear | B | ||

| SuperBike 996 | '00-'01 | Front | B | /S/SPS/R |

| SuperBike 998 | '02-'04 | Front | B | /R/S/S BOSTOM/MATRIX/FE bipost/FE monoposto |

| SuperBike 999 | '03-'07 | Front | B | S AMA replica/S/R XEROX/R |

| SuperBike 999 | '03-'07 | Rear | B | |

| SuperBike 1098 | '07-'09 | Front | B | /R /R Bayliss /S /S Tricolore |

| SuperBike 1198 | '09-'11 | Front | B | /SP/S /S Corse/R /R Bayliss |

| SuperBike 1199 | '12-'13 | Front | B | Panigale/S/S TRIC /S ABS /Panigale R |

| SuperBike 1299 | Front | B | PanigaleS /Panigale R | |

| SUPERSPORT 400SS | '93-'97 | Front | B | |

| SuperSPORT 600SS | '91-'97 | Front | B | |

| SuperSPORT 620Sport | 2003 | Front | B | |

| SuperSPORT 750SS | '91-'97 | Front | B | /ie/sport |

| SuperSPORT 750SS | '91-'02 | Rear | B | |

| SuperSPORT 750SS | '00-'02 | Front | B | |

| SuperSPORT 800SS | 2003 | Front | B | /sport |

| SuperSPORT 800SS | 2003 | Rear | B | |

| SuperSPORT 800SS | '05-'07 | Front | B | |

| SuperSPORT 900 SS | '91-'98 | Front | B | /ie/sport /FINAL ED |

| SuperSPORT 900 SS | '00-'02 | Front | B | |

| SuperSPORT 900 SS | '00-'02 | Rear | B | |

| SuperSPORT 936 | '17- | Front | B | /S |

| SuperSPORT 1000SS | '03-'04 | Front | B | |

| SuperSPORT 1000SS | 2005 | Front | B | Compatible with genuine product number No.81910781AA |

| SuperSPORT 1000SS | 2006 | Front | B | |

| SuperSPORT 1000SS | '03-'06 | Rear | B |

KTM

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| 125 DUKE | '14-'16 | Front | A | |

| 125 DUKE | '14-'16 | Front | A1 | H-80 |

| 125 DUKE | '14-'16 | Rear | E | 125 DUKE | '17- | Front | A |

| 125 DUKE | '17- | Front | A1 | H-80 |

| 200 DUKE | '14-'16 | Front | A | |

| 200 DUKE | '14-'16 | Front | A1 | H-80 |

| 200 DUKE | '14- | Rear | E | 200 DUKE | '17- | Front | A |

| 200 DUKE | '17- | Front | A1 | H-80 |

| 250 DUKE | '14-'16 | Front | A | |

| 250 DUKE | '14-'16 | Front | A1 | H-80 |

| 250 DUKE | '14- | Rear | E | 250 DUKE | '17- | Front | A |

| 250 DUKE | '17- | Front | A1 | H-80 |

| 390 DUKE | '14-'16 | Front | A | |

| 390 DUKE | '14-'16 | Front | A1 | H-80 |

| 390 DUKE | '14- | Rear | E | 390 DUKE | '17- | Front | A |

| 390 DUKE | '17- | Front | A1 | H-80 |

| 690 DUKE | Front | B | ||

| 690 DUKE | Rear | B | Specifications :Screws on both sides,Need to be transplanted from genuine chain adjuster. | |

| 790 DUKE | Front | B | ||

| 790 DUKE | Rear | B | Specifications :Screws on both sides,Need to be transplanted from genuine chain adjuster. | |

| 890 DUKE | Front | B | ||

| 890 DUKE | Rear | B | Specifications :Screws on both sides,Need to be transplanted from genuine chain adjuster. | |

| 950 SUPER MOTO | Front | B | /R | |

| 990 SUPER DUKE | Front | B | ||

| 990 SUPER MOTO | Front | B | /R /T /T ABS | |

| 390 ADVENTURE | Front | A | ||

| 390 ADVENTURE | Front | A1 | H-80 | |

| 390 ADVENTURE | Rear | E | ||

| 1090 Adventure | Pviot | S | ||

| 1190 Adventure | Pviot | S | ||

| 1290 Adventure | Pviot | S | ||

| 1290 Super Adventure | Pviot | S | ||

| 1290 Super Duke R | '14-'19 | Front | B | /ABS |

| 1290 Super Duke R | Pviot | S | /ABS | |

| 1290 Super Duke GT | Front | B | ||

| 1290 Super Duke GT | Pviot | S | ||

| RC125 | '14-'16 | Front | A | |

| RC125 | '14-'16 | Front | A1 | H-80 |

| RC125 | '14- | Rear | E | |

| RC125 | '17- | Front | A | |

| RC125 | '17- | Front | A1 | H-80 |

| RC250 | '14-'16 | Front | A | |

| RC250 | '14-'16 | Front | A1 | H-80 |

| RC250 | '17- | Front | A | |

| RC250 | '17- | Front | A1 | H-80 |

| RC250 | '14- | Rear | E | |

| RC390 | '14-'16 | Front | A | |

| RC390 | '14-'16 | Front | A1 | H-80 |

| RC390 | '14- | Rear | E | |

| RC390 | '17- | Front | A | |

| RC390 | '17- | Front | A1 | H-80 |

| RC8 | Front | B | ||

| RC8 | Pviot | S | /ABS | |

| RC8 | Rear | B | Specifications :Screws on both sides,Need to be transplanted from genuine chain adjuster. |

MV AGSUTA

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| BRUTALE 675 | Front | B | ||

| BRUTALE 675 | Front | B | ||

| BRUTALE 800 | Front | B | ||

| Brutale | '11-'12 | Front | B | /920 /990 /1090 /1090R /1090RR |

| Brutale | 2013 | Front | B | /1090 /1090R /1090RR |

| Dragster | Front | B | ||

| F3 675 | Front | B | ||

| F3 675 | Front | B | Ver.Ohlins front fork kit "RDTL002312" | |

| F3 800 | Front | B | ||

| F3 800 | Front | B | Ver.Ohlins front fork kit "RDTL002312" | |

| F4 1000 | '06-'09 | Front | B | /1000R 1+1 /Senna /1000R /312R 1000 1+1 /312R 1000 /312RR 1078 |

| F4 1000 | '10- | Front | B | /Frece tricolore /R /S |

| F4 1000 | '10- | Front | B | /RR /RC |

| RIVALE 800 | Front | B | ||

| Stradale 800 | Front | B | ||

| Turismo Veloce 800 | Front | B | /ED. 1 /Lusso |

APRILIA

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| Caponord | '15-'16 | Front | B | 1200 / Rally |

| Dorsoduro 750 | '09-'16 | Front | B | |

| Dorsoduro 1200 | '07-'14 | Front | B | Mana /Mana GT |

| Falco | '00-'03 | Front | B | |

| Mille | '00-'03 | Front | B | Mille-R |

| RSVR | '04-'09 | Front | B | Factory |

| RSV4 | '09-'16 | Front | B | |

| RSV4 | '09-'16 | Rear | B | |

| Shiver | '07-'16 | Front | B | |

| Tuono | '02-'16 | Front | B | V4 1100 |

MOTO GUZZI

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| NEVADA | '03-'13 | Front | B | |

| NEVADA | '04-'13 | Rear | B | |

| V7 | '08- | Front | B | /Rough /cafe /Carbon /Carbon Shine /Milano /Racer / Specail /Stone |

| V7 | '08- | Rear | B | /Rough /cafe /Carbon /Carbon Shine /Milano /Racer / Specail /Stone |

| V85TT | Front | B | /TT /TT Premium | |

| V85TT | Rear | B | /TT /TT Premium | |

| V9 | Front | B | /Bobber /Bobber Sport /Roamer | |

| V9 | Rear | B | /Bobber /Bobber Sport /Roamer |

PEUGEOT

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| DJANGO50/125/150 | Front | E |

SWM

| Name | Year | Part | Price type | Remark |

|---|---|---|---|---|

| Gran Milano400 | Front | B | ||

| Gran Milano400 | Rear | B | ||

| OUTLAW125 | Front | B | ||

| OUTLAW125 | Rear | B |

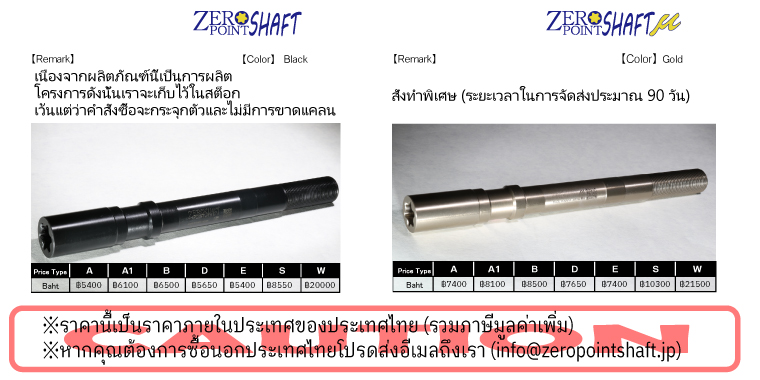

●Type A ฿6000

●Type A1 ฿6750 with Tool

●Type B ฿7200

●Type D ฿6300

●Type E ฿9500

●Type S ฿10250

Zero Point Shaftμ [Price type]

●Type A ฿8000

●Type A1 ฿8750 with Tool

●Type B ฿9200

●Type D ฿8300

●Type E ฿11500

●Type S ฿12250

*This price is the domestic price in Thailand.(VAT INCLUDED)

*If you would like to purchase outside Thailand, please give us email. (info@zeropointshaft.jp)